Products

Description:

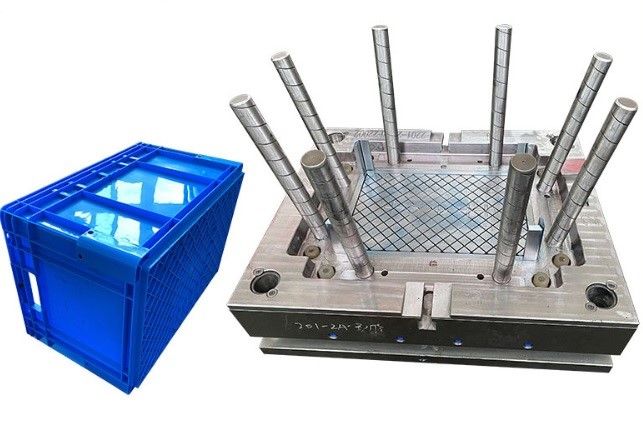

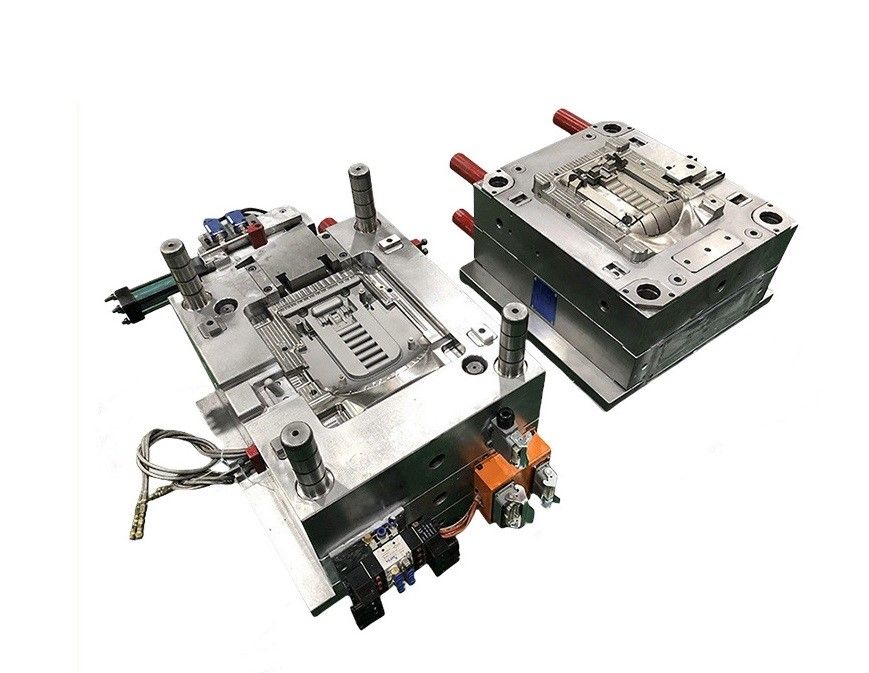

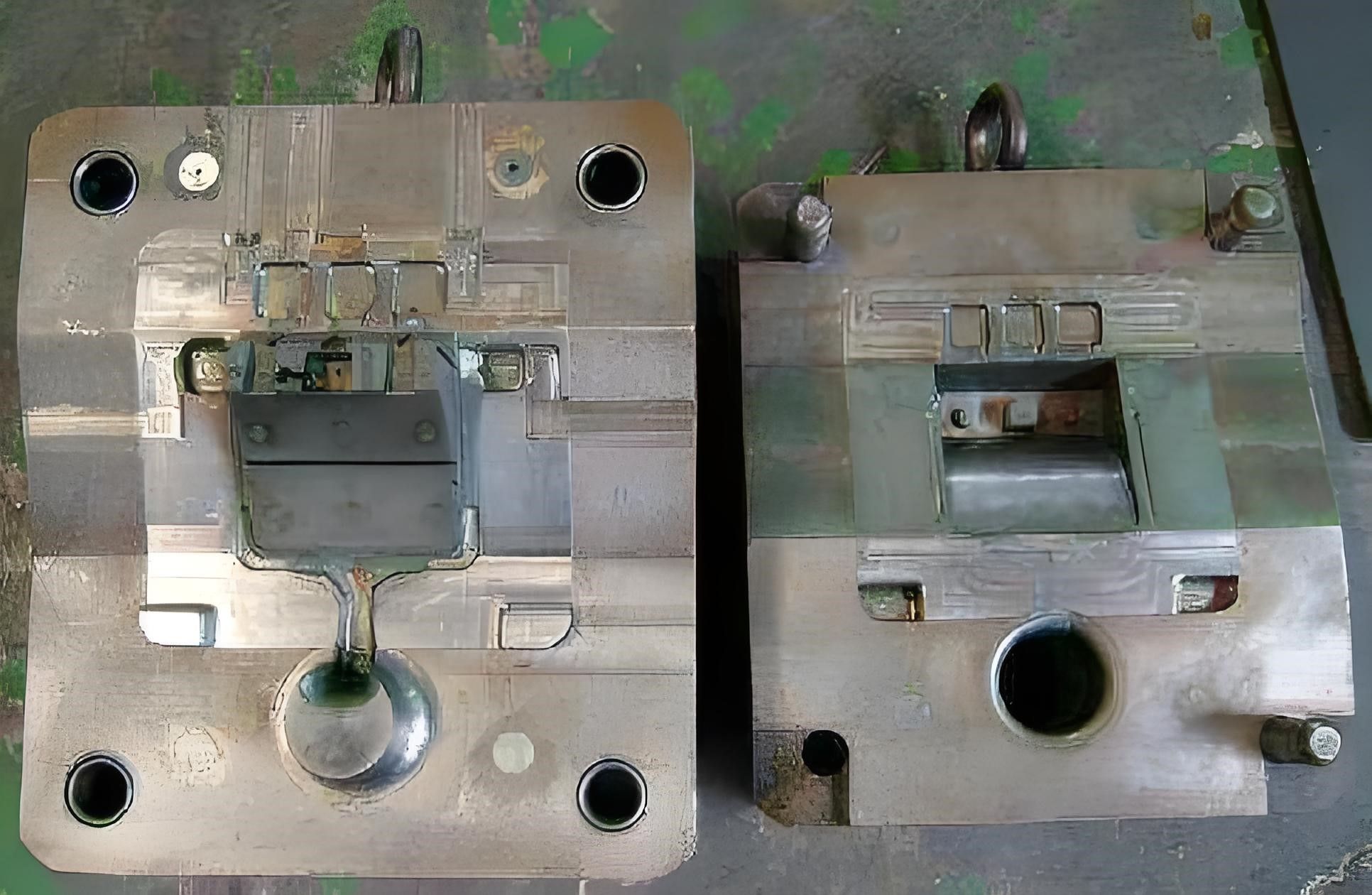

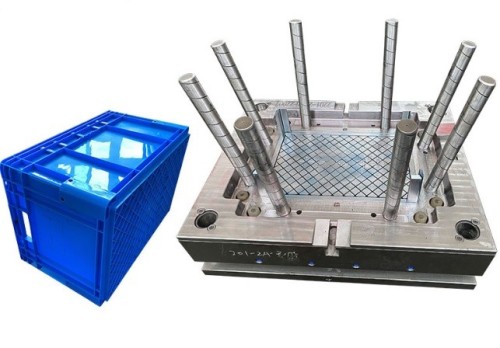

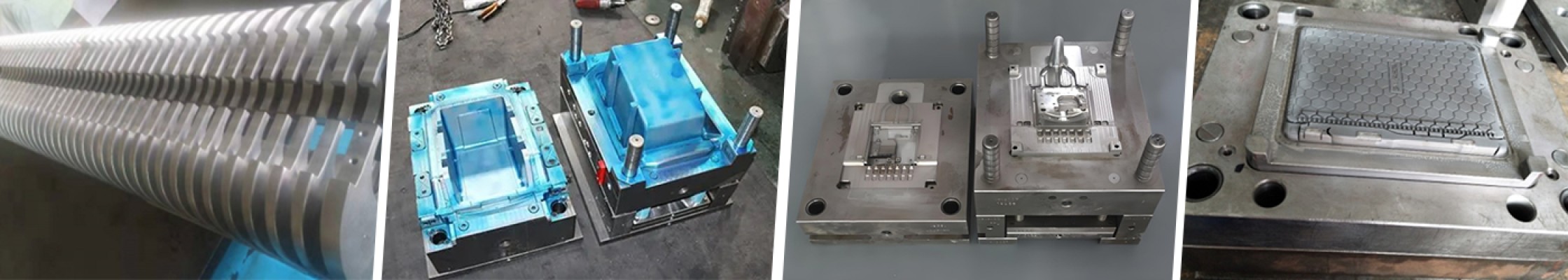

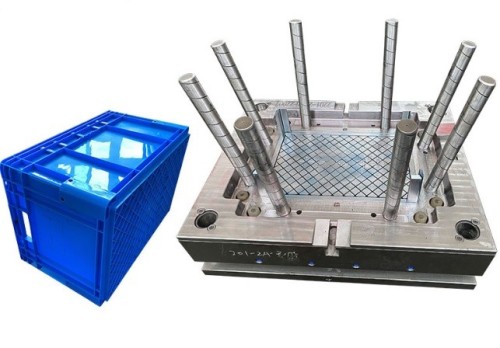

Our Industrial-Grade Plastic Injection Moulds are engineered to meet the highest standards of precision and durability. Designed with advanced tooling technology and high-strength steel, these moulds deliver accurate, reliable, and efficient production for industries worldwide.

Widely used in the manufacturing of automotive parts, navigation devices, digital cameras, printers, speakers, mobile phones, electronic housings, household appliances, helmets, and PET products, they provide flexible solutions for both prototype development and large-scale production.

By combining innovative engineering with superior materials, our moulds help manufacturers reduce costs, enhance product quality, and increase production efficiency.

Key Features:

-

Precision Tooling – Maintains exact tolerances for complex, detailed designs.

-

Extended Lifespan – Built with premium steel and heat treatment for long-term use.

-

High Productivity – Optimized mould flow and cooling systems to shorten cycle times.

-

Versatile Applications – Suitable for automotive, electronics, appliances, PET, and consumer goods.

-

Consistent Quality – Ensures stable performance across high-volume production runs.

-

Scalable Solutions – Supports rapid prototyping as well as mass manufacturing.

-

Cost-Optimized Design – Engineered to lower production costs while maximizing output.