Products

Description:

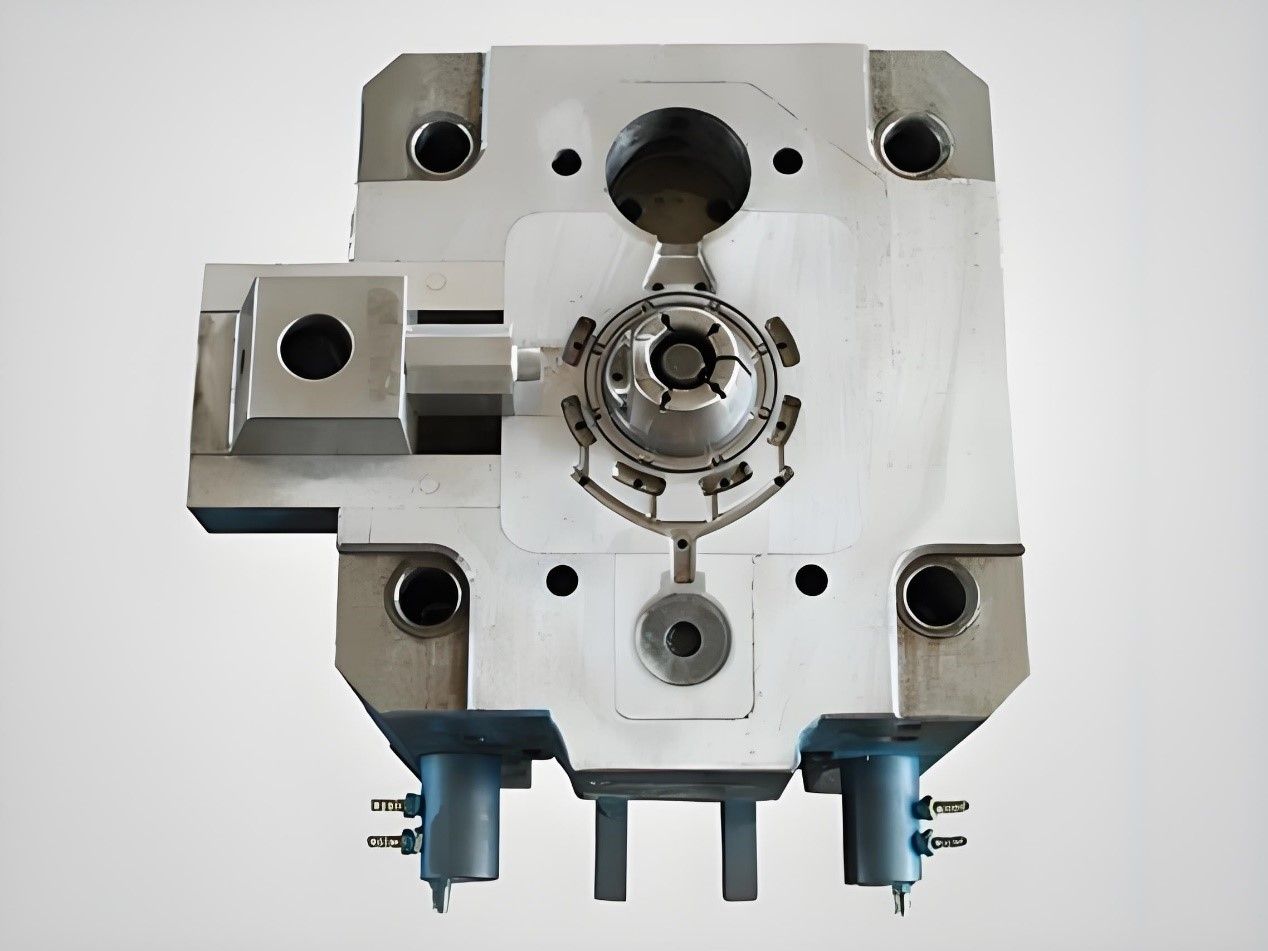

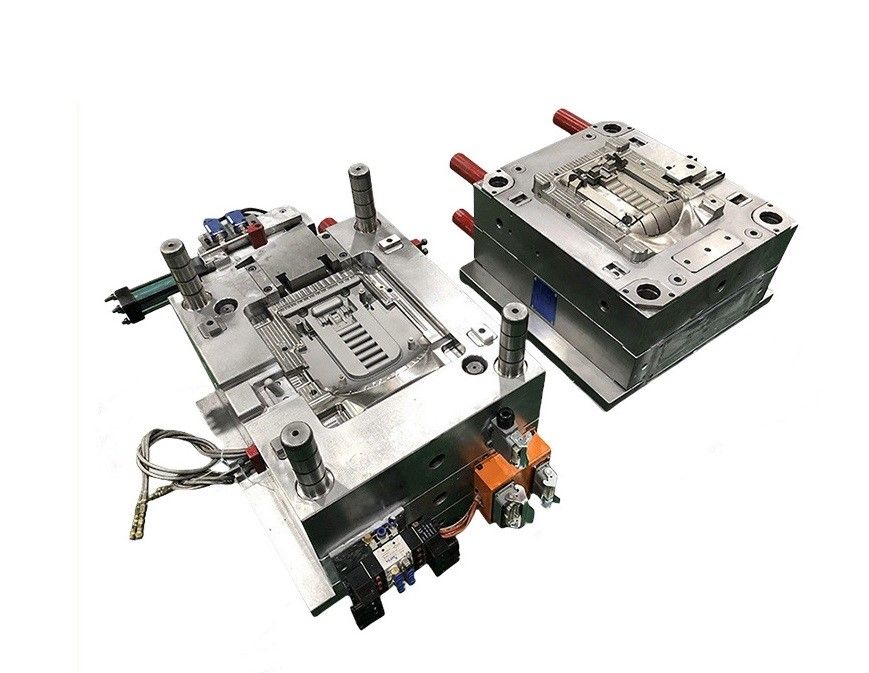

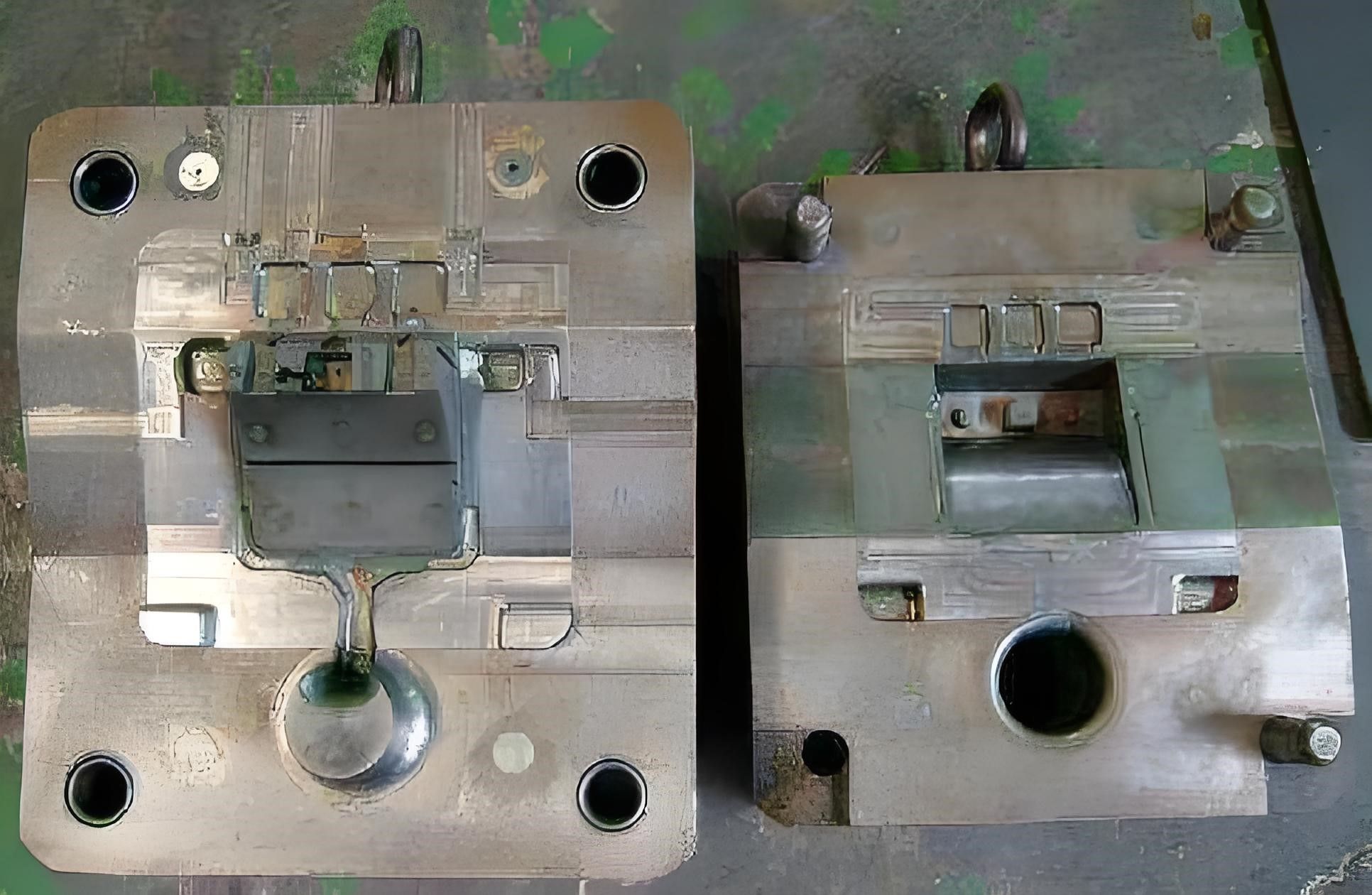

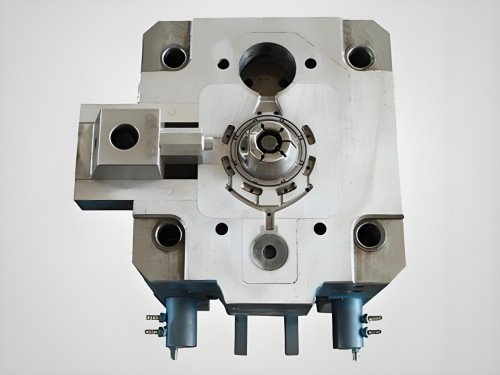

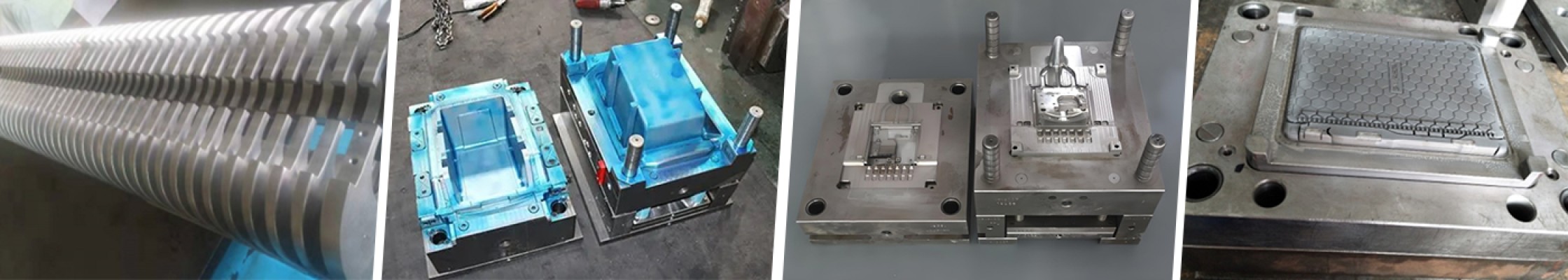

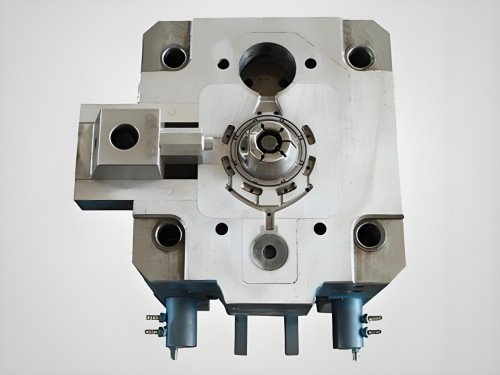

Our Die Casting and Prototype Moulds are designed to deliver precision, durability, and efficiency for a wide range of industries. Manufactured with advanced CNC machining and premium-grade materials, these moulds support both prototype development and large-scale production. From automotive parts, navigation systems, and digital cameras to mobile phones, printers, blue speakers, helmets, household appliances, PET products, and plastic toolboxes, our moulds ensure consistent quality, superior finishing, and long service life.

Engineered for versatility, they provide manufacturers with cost-effective, high-accuracy solutions for plastic and metal components across multiple sectors.

Key Features:

-

Precision Engineering – CNC-machined for accuracy and reliability.

-

Versatile Applications – Suitable for automotive, electronics, appliances, medical, and consumer products.

-

Prototype & Mass Production Ready – Supports early-stage development and scalable manufacturing.

-

Durable Construction – High-strength tool steel for extended mould life.

-

Superior Surface Finish – Ensures defect-free, high-quality end products.

-

Efficient Cooling System – Reduces cycle time for faster production.

-

Custom Design Options – Tailored to meet client-specific requirements.